Needle Peening Training – SPIKER®

This course covers the theoretical and practical aspects of Needle Peening with the Spiker®. The participants will learn the basis of shot peening and the specifics related to Needle peening. In the practical session, the participants will use a Spiker® tool to gain hands-on experience with the process while generating a saturation curve. A written exam is given to the participants and a passing grade of 70% will provide a Certificate of Achievement.

outline

Introduction to Peening

- Why do we peen?

- Applications in Aerospace

- How Peening Works

- Importance of Quality Peening

- Considerations before Peening

Peening Intensity

- Intensity = Impact Force

- Thickness of the layer of Compression

- Finding the Intensity

- Generating a Saturation Curve

- Practical Saturation Curve

Peening Coverage

- What is Coverage?

- How is Coverage measured?

- 100% Coverage

- 200% Coverage

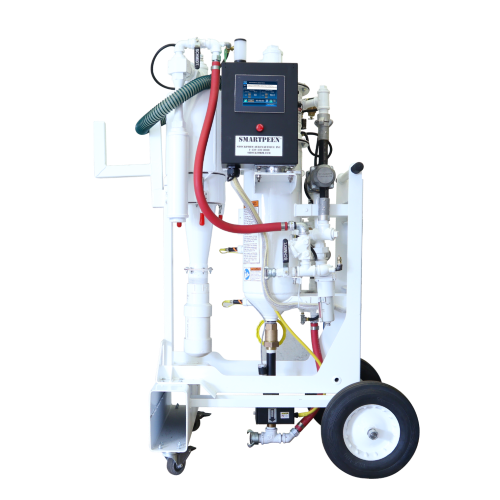

Using the Spiker® Tool

- Features

- Linear Head

- Single Needle Head

- Spiker® Connectors

- Spiker® Menus Spiker® Log

Spiker® Peening Specific

- Needle Peening Applications

- Limitations

- Movement of the Head

- Cap wear verification

- Removing the Cap

- Changing the Needles

- Needle wear verification

Spiker® Practical

Each participant will setup the unit and generate a saturation curve. The instructor will verify the technique and the intensity obtained with the Spiker® using the integrated saturation curve solver.

Exam

The student who completes the exam with a grade of 70% and higher will obtain a certificate of achievement.

Time Required

6-8 hrs