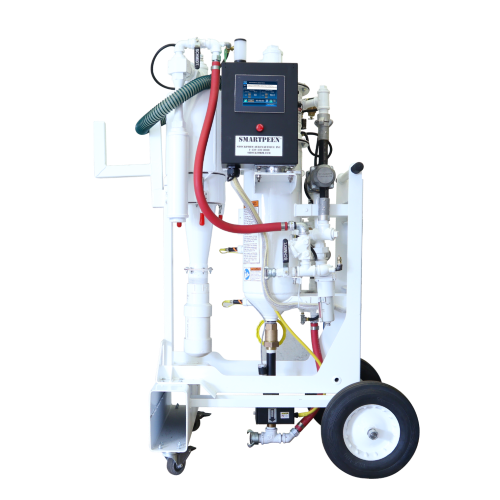

Automated Peening Machine Training

This training covers the practical aspects of using an automated peening machine including health and safety, intensity, coverage, machine maintenance, machine calibration and parts inspection.

outline

Operation of the equipment

Health and safety in shot peening

- Emergency stops.

- The dead man switch.

- Machine supply points.

- Working with carbide tools.

- Media projection dangers.

- Working with robotic/CNC manipulators.

- Media manipulation.

- Static electricity.

- Threaded components use in shot peening.

Parameter selection – Intensity and coverage

- Almen fixtures – specific and generic.

- How to choose the parameters to ensure the right intensity and coverage.

- How to build a saturation curve.

- Determine the effects of the variation of a parameter on the intensity.

- How to find the critical parameter limits to respect the intensity.

Parameters validation – Parts inspection

- The importance of validating and completing the work instructions using a test part.

- How to verify that the part has the right coverage.

- Procedures after a machine alarm to ensure part conformance.

- Detection of surface defects before shot peening.

- Detection of surface defects after shot peening.

Part manipulation and masking

- How to manipulate parts correctly and safely.

- The importance of a good parts arrangement.

- The objectives of masking.

- The principles of a good masking that conforms to client requirements.

- Masking instructions.

- Masking types.

- Tools used.

Production shot peening

- Almen testing during production.

- Media analysis.

- Sampling for big productions.

Machine maintenance and calibration

- How to verify wear on nozzles, lances and blast hoses.

- How to verify the pinch valves, media adder and the dust collector.

- How to diagnosis the more frequent machine problems.

- Machine axes calibration.

- Machine movement speed calibration.

- Machine repeatability verification.

- How to test the predetermined machine limits.

Exam

The student who completes the exam with a grade of 70% and higher will obtain a certificate of achievement.

Time Required

6-8 hrs