The Spiker®-ES Controlled Pneumatic Needle Peening, for on-aircraft operations and on mounted engines

Shockform is the proud inventor and manufacturer (OEM) of the Spiker®-ES.

The only needle peening tool designed to peen hard-to-reach geometries and eliminate the risk of FOD.

The Spiker®-ES has been developed with aero engines manufacturers for repairs directly on the engine with no risk of Foreign Object Damage (FOD). With the Spiker®-ES, peening is performed using tungsten carbide needles and the process parameters are continuously monitored, controlled and recorded. The Spiker®-ES allows the needle peening of complex geometries where flapper peening is usually impossible. Perfectly suited for work on engine components, but also on aircraft wings, internal structures and on landing gears.

The Spiker®-ES also includes Shockform’s latest innovation: the E-Strip®, a real-time peening intensity measurement device calculating the intensity in seconds, thus saving a huge amount of time. The E-Strip® offers a more reliable feature for your peening activities and it is also meant to replace single use Almen strips, making needle peening with the Spiker®-ES more eco-friendly and green.

The Spiker®-ES has the following features:

Process Advantages:

- Fast and Effective Repair Peening

- Reliable and Repeatable

- Peening intensity measurement in real time

- Minimal Risk of Foreign Object Damage (FOD)

- Very Smooth Surface Finish

- Deep Surface Residual Stresses

- Fatigue Life that is equivalent and often much better than conventional technique

- Easy application on aero-engine components with significant cost saving potential.

Equipment Advantages:

- Certified AMS 2545, Nadcap 7117/6, J441, J442, J443, J2597

- Small Head for Hard-to-Reach Areas

- Each Needle Tracked Individually

- User Friendly Color Interface

- Process Data Saved to USB key

- Easy to Print Report

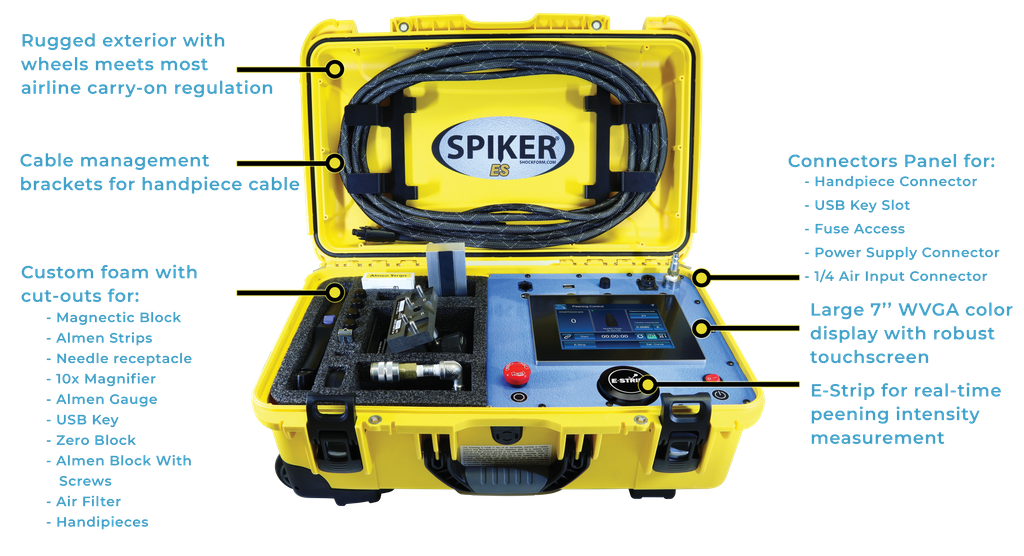

- Everything included in one Small Case.

AVAILABLE KITS

SPIKER®-ES (SPK-105)

The Spiker®-ES SPK-105 kit includes all the components of the SPK-104 kit plus a second handpiece.

SPIKER®-ES (SPK-104)

The Spiker®-ES SPK-104 kit includes all the components of the SPK-102 kit plus an Almen Gage TSP3B (FPG-1000), 100 Almen strips (A-1), a magnetic holder (FPM-1000) and an extra set of caps (SPK-LH4-3CK).

It features a large and robust color touch screen user interface with an integrated stopwatch and countdown timer and a saturation curve solver for intensity calculations. It offers the choice of multiple languages and measurement units, USB data recording of process parameters and a 25 feet cable (SPK-CA) between the handpiece and the controller. The handpiece has a small and powerful linear head with 4 needles and 3 interchangeable caps (SPK-LH4-3CK) to peen on flat surfaces, inner radii and outer radii.

The unit also comes with a 10X Magnifier (MAG-10X), a USB key (PRO-044), an electrical power cord (PRO-018), an air filter (SPK-065), Allen keys (SPK-060-AK1.5 and SPK-060-AK1.3) a Certificate of Calibration traceable to NIST, Certificates of Conformance and a User Manual.

The Spiker® SPK-104 also includes an Almen Gage TSP3B (FPG-1000), 100 Almen strips (A-1), a magnetic block (FPM-1000) and an extra set of caps (SPK-LH4-3CK).

Electrical supply 110V to 220V, 50-60Hz, Weight = 34 lbs, Dimensions: 22 in x 14 in x 9 in

* An additional Single needle handpiece may be purchased separately.

SPIKER®-ES (SPK-102)

The only pneumatic needle tool invented for controlled pneumatic needle peening, straightening and forming. The Spiker®-ES SPK-102 is for companies that already have an Almen gage, Almen strips and a magnetic block.

It features a large and robust color touch screen user interface with an integrated stopwatch and countdown timer and a saturation curve solver for intensity calculations. It offers the choice of multiple languages and measurement units, USB data recording of process parameters and a 25 feet cable (SPK-CA) between the handpiece and the controller. The handpiece has a small and powerful linear head with 4 needles and 3 interchangeable caps (SPK-LH4-3CK) to peen on flat surfaces, inner radii and outer radii.

The unit also comes with a 10X Magnifier (MAG-10X), a USB key (PRO-044), an electrical power cord (PRO-018), an air filter (SPK-065), Allen keys (SPK-060-AK1.5 and SPK-060-AK1.3) a Certificate of Calibration traceable to NIST and a User Manual.

Electrical supply 110V to 220V, 50-60Hz, Weight = 24 lbs, Dimensions: 22 in x 14 in x 9 in

* An additional Single needle handpiece may be purchased separately.

| Controller Dimensions | L22.0″ × W14.0″ × H9.0″(L559mm × W356mm × H229mm) |

|---|---|

| Controller Weight | 21 lbs (9.5 Kg) empty, 34 lbs (15.4 kg) fully loaded |

| Protection | Weather proof Impact resistant NK-7 Resin Exterior |

| CPU | Intel® Atom N2600 Dual Core |

| Control Signal | Closed Loop Pressure Feedback using Proprietary Control Software |

| Response Time | 0.3 to 0.5 sec |

| Repeatability | +/- 1 PSI |

| Pressure Monitoring | Continuous |

| Alarm | Ajustable when pressure is out of range or needles not moving |

| User Input curves | Almen Intensity vs. RPM for 5 operators |

| Data Recording | Yes, through included 2 Gb. Memory key |

| Real-Time Clock | Yes |

| Brightness Adjustment | Yes |

| Calibration Setup | Yes |

| Memory | Flash = 2GB Standard |

| Display | 7 inch 800×480 Color Display |

| Keyboard | Touch Screen |

| Pressure Input | 0-120 Psi |

| Operating Temp. | 32°F to 122°F (0°C to +50°C) |

| Sensor Type | Integrated in head |

| Handpiece Cord Length | 25 Ft (7.7m) |

| Electrical Input | 100-240V, 50/60 Hz, 3.0 A |

| Certification | CE |

| Specification | AMS 2545, Nadcap 7117/6 |

| Picture | Model No. | Product: Monitors |

|---|---|---|

|

SPK-047-NEEDLE | Full carbide needle 0.60 mm tip (equivalent to S230) |

|

SPK-047-NEEDLES, x4 | Full carbide needle 0.60 mm tip (equivalent to S230) |

| SPK-LH4-HEAD |

Hand piece with 4 needles linear head (radius,flat surface) |

|

| SPK-SH1-HEAD | Hand piece with (1) single needle head (corner) | |

|

SPK-LH4-3CK | Kit of 3 bottom cap for Spiker Head (Flat, Inner Radius, Corner Edge) |

|

SPK-022 | Separate bottom cap for Spiker Head Flat SPK-H104F |

|

SPK-020 | Separate bottom cap for Spiker Head Inner Radius SPK-H104R |

|

SPK-021 | Separate bottom cap for Spiker Head Corner Edge SPK-H104E |

|

SPK-CABLE AIR/ELEC | Additional hand piece cable 25 feet (7.7 meters) |

|

SPK-065 | Additional Air Filter |

|

FPM-1000 | Magnetic Strip Holder 2″ X 7″ X 1″ |

|

FPG-1000 | Almen Gage |

|

Strips A-1 | Almen Strips |

Spiker®-ES Needle Peening for Controlled Pneumatic Needle Peening Features