Flapper Peening Training– Flapspeed® PRO

This course covers the theoretical and practical aspects of Flapper Peening. The participants will learn the basis of shot peening and the specifics related to flapper peening. In the practical session, the participants will use a FlapSpeed® PRO to gain hands-on experience with the process while generating a saturation curve. A written exam is given to the participants and a passing grade will provide a Certificate of Achievement.

outline

Introduction to Peening

- Why do we peen?

- Applications in Aerospace

- How Peening Works

- Importance of Quality Peening

- Considerations before Peening

Peening Intensity

- Intensity = Impact Force

- Thickness of the layer of Compression

- Finding the Intensity

- Generating a Saturation Curve

- Practical Saturation Curve

Peening Coverage

- What is Coverage?

- How is Coverage measured?

- 100% Coverage

- 200% Coverage

Exploring Flapper Peening

- How does Flapper Peening work?

- Flapper Peening Applications

- Limitations

- Type of Flaps

- Type of Mandrels

- Changing the Flaps

- Movement of the Flap

- Stand-Off Distance

- Arc Height Conversion

- Typical blending Instructions

- Audits and Certifications

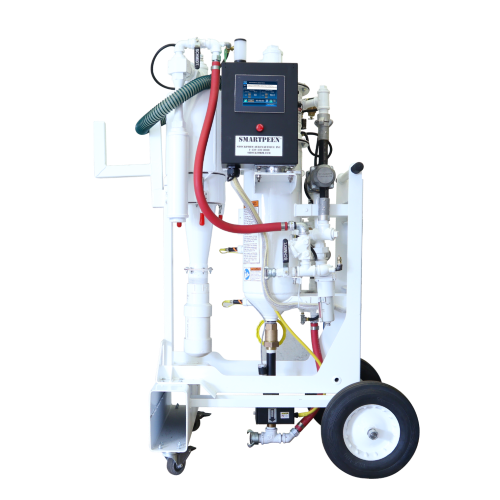

Using the FlapSpeed® PRO

- Why a Flapper Peening Controller

- Features of the FlapSpeed® PRO

- Straight Handpiece

- 90 degree Handpiece

- Connectors

- Menus

- Log

FlapSpeed® PRO Practical

Each participant will setup the unit and generate a saturation curve. The instructor will verify the technique and the intensity obtained with the FlapSpeed® PRO using the integrated saturation curve solver.

Exam

The student who completes the exam with a grade of 70% and higher will obtain a certificate of achievement.

Time Required

6-8 hrs