Training

Shockform has been delivering peening related training worldwide for more than 10 years. Our senior trainers each have more than 30 years of experience in the Aerospace industry and are members of the SAE AMEC and J SPEC committees on surface enhancement.

Shockform’s training team has trained hundreds of students since 2013 in both English and French.

Flapper Peening Training

FLAPSPEED® PRO

This course covers the theoretical and practical aspects of Flapper Peening. The participants will learn the basis of shot peening and the specifics related to flapper peening. In the practical session, the participants will use a FlapSpeed® PRO to gain hands-on experience with the process while generating a saturation curve. A written exam is given to the participants and a passing grade will provide a Certificate of Achievement.

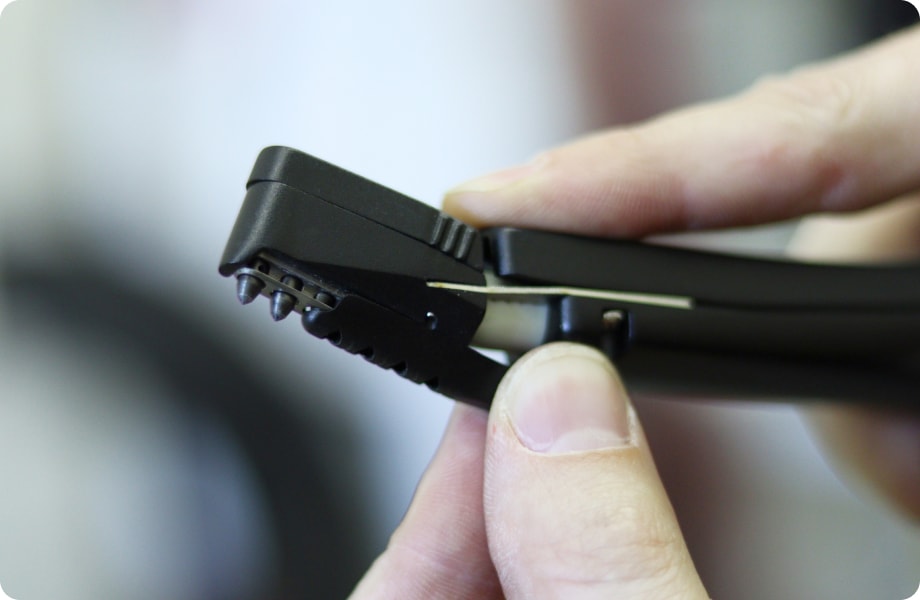

Needle Peening Training

SPIKER®

This course covers the theoretical and practical aspects of Needle Peening with the Spiker®. The participants will learn the basis of shot peening and the specifics related to Needle peening. In the practical session, the participants will use a Spiker® tool to gain hands-on experience with the process while generating a saturation curve. A written exam is given to the participants and a passing grade of 70% will provide a Certificate of Achievement.

Shot Peening Training

SMARTPEEN®

This course covers the Conventional Shot Peening process using the SmartPeen® mobile peening unit with vacuum recovery. The participants will learn the basis of shot peening and the specifics related to using the SmartPeen® mobile peening unit with vacuum recovery. In the practical session, the participants will use a SmartPeen® to gain hands-on experience with the process while generating a saturation curve. A written exam is given to the participants and a passing grade of 70% will provide a Certificate of Achievement.